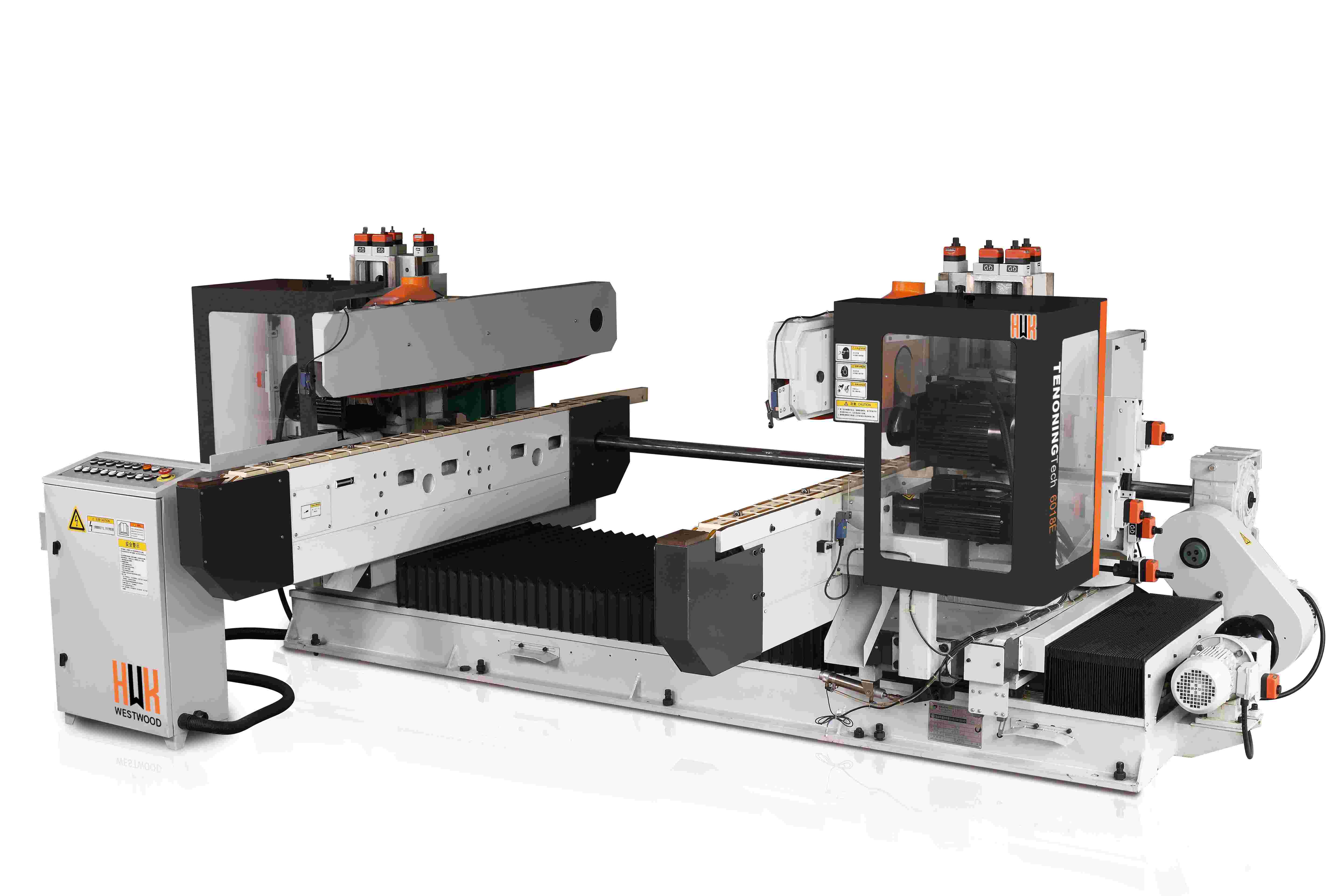

WMD60E Series Double End Tenoner

|

Specification & type |

WMD6018E |

|

|

Working Thickness (mm) |

10~ 50 |

|

|

Working Width (mm) |

280 ~ 1850 |

|

|

Cutting circles(max~min) (mm) |

Left Saw unit |

Ø160 ~ Ø200 |

|

Right Saw unit |

||

|

Left cut-off Saw |

Ø250 ~ Ø300 |

|

|

Right cut-off Saw |

||

|

Left and right milling unit |

Ø140 ~ Ø160 |

|

|

Spindle diameters(mm) |

Left Saw unit |

Ø25.4 |

|

Right Saw unit |

||

|

Left cut-off Saw |

Ø35 |

|

|

Right cut-off Saw |

||

|

Left and right milling unit |

Ø40 |

|

|

Cutterhead length(mm) |

|

95 |

|

Basic motor powers |

Left Saw unit |

3kW/4HP |

|

Right Saw unit |

3kW/4HP |

|

|

Left cut-off Saw |

5.5kW/7.5HP |

|

|

Right cut-off Saw |

5.5kW/7.5HP |

|

|

Left and right milling unit |

2×5.5kW/7.5HP |

|

|

Feed |

3kW/4HP |

|

|

Widen |

1.1kW/1.5HP |

|

|

Total motor power (kW) |

31.75kW/43.1HP |

|

|

Feed speed (m/min) |

6~ 18 |

|

|

Saw speed(r/min) |

3000 |

|

|

Spindle speed (r/min) |

7500 |

|

|

Dust outlet diameter (mm) |

Ø120 |

|

|

Overall machine dimensions approx (L×W×H) (mm) |

3500×2350×1500 |

|

|

Weight (tons approx) (T) |

4 |

|

Note:Any variation to the specification above mentioned will not be further notified since the product specification and design keeps on changing all the time